The heavy burden of contract management and the risk posed by human management have led many companies to introduce contract management systems. Contract management systems promise managers time savings, long-term cost reductions, increased verifiability, future stability and risk reduction. Sources: 2

In response to this increased demand, a variety of contract management systems have come onto the market. These solutions provide contract lifecycle management software that can be integrated into other systems such as accounting, utility and resource planning systems to take full advantage of contract lifecycle management. They also provide services that help differentiate them from the competition and ensure that the core needs of contract managers are met. Sources: 0, 2

With contract lifecycle software, users can reduce supplier risk and increase contract visibility. Sources: 0 Contract management software helps eliminate depreciation and inefficiencies by providing centralized, organized access to your company contracts. Contract management systems enable companies to create new contracts, track the status of existing contracts and ensure that employees, suppliers and customers meet the specified requirements. This guide will help buyers to find the best contract management solution for their needs. Sources: 4, 10

Contract management software gives your group the tools it needs to share contracts with employees, place and manage orders, analyze key terms, review contracts, streamline processes and results, and track key deadlines. Contract management software gives lawyers more time for strategic, high-quality work by enabling them to update contracts more frequently. Sources: 10

Contract management software is the most effective and cost-effective way to streamline the contract management and add value to your office. Complete contract management solutions offer comprehensive features that provide you with everything you need to get your job done. They cover all aspects of the contract lifecycle and eliminate the need for other legal technologies. Sources: 7, 10

In addition to duplicating functions, contract management software can serve as a digital filing cabinet for organizing contracts. You can also set up notifications in the software to alert parties to upcoming deadlines throughout the contract life cycle. Sources: 6

It is important to consider the needs of your organization when studying the characteristics and benefits of contract management tools. Many solutions allow contracts to be shared between internal and external partners, but if you have security or accessibility concerns, you should look at how contracts are passed on to external partners. If you are looking for the best contract management solution for your business, you should consider what the full performance of the solution must be for your business. Sources: 5, 6

Finding the right contract management solution has become an easy way to reduce operating costs, increase productivity and keep a step ahead of customers’ expectations. The best contract management solutions for your business are obvious and should be at the top of your list. For enterprise contract management, a solution that is easy to implement, easy to use, and accessible to everyone is something you should be looking for. Sources: 3, 9

Before you use a search engine to search for a contract management system, you must first research your ranks. Just as you need to know your desired storage size, computing power, and operating system before you start browsing laptops, you also need to determine the needs of your end users before looking for contract management systems. Sources: 1

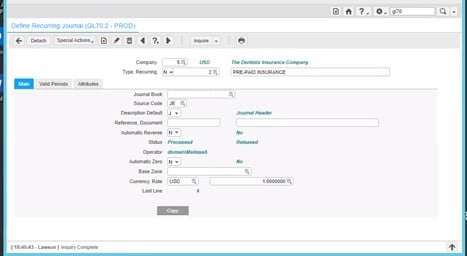

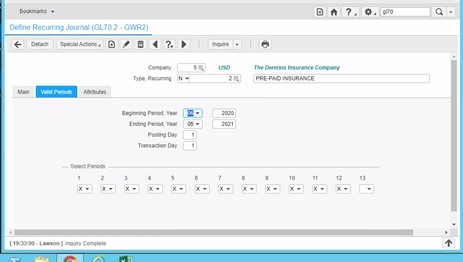

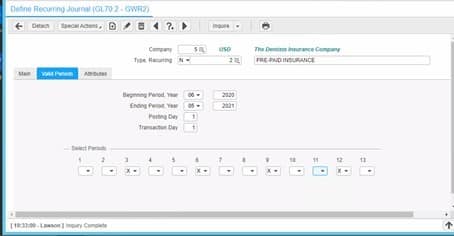

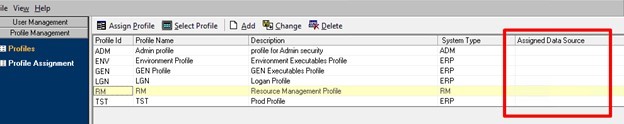

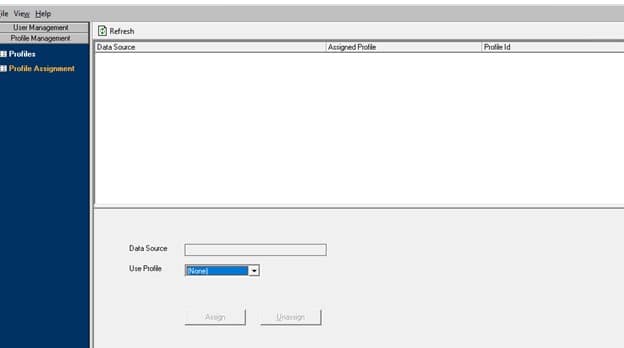

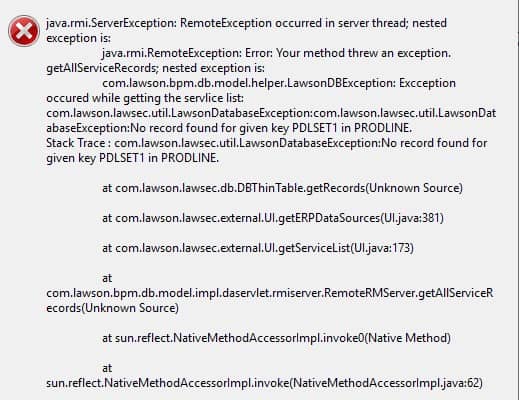

Remember that the benefits of a contract management system can not be maximized if it is isolated from other business processes and systems within the organization. Contract management systems are an option for determining and linking contracts, projects, invoices and other documents and email correspondence. They can also be integrated with other solutions of the organization such as ERP, NAV, SAP, MS Outlook, etc. Sources: 8

For example, it is possible to view not only current contracts, but also links to specific vendor correspondence, invoices that are generated in the course of implementation, how much revenue they generate for the organization and how much the organization intends to raise. Sources: 8

Companies often use contract management software in the supply chain to process supplier and distribution transactions with suppliers, conclude contracts, and keep inventories and retail operations running smoothly. Sales teams often integrate contract management systems into their Customer Relationship Management (CRM) platforms to manage sales contracts, renewal negotiations, manufacturing contracts, car leasing, etc. Sources: 2

Companies could also consider a contract management system with a modular suite that allows them to select different modules as needed. For example, an organization with an agreement involving multiple internal and external parties would like to consider a solution that would allow it to write conditions for different stakeholders, automate approval processes, send automated notifications, track milestones, enforce contractual obligations, and integrate with an external ERP or CRM solution. Sources: 4

Contract management software facilitates the creation, signature and distribution of legal documents. It helps your team organize contracts in a centralized location, reducing the time it takes to send documents to partners during negotiations. Contract management providers also recognize the advantages and opportunities that data analysis can offer to accelerate decision-making processes across the entire company. Sources: 4, 6

Contract Lifecycle Management (CLM) is a software system that manages and organizes your contract process from start to finish. Attention to this phase is explained by the inclusion of the term life cycle in the CLM name: a CLM system is designed for the entire life cycle of your contract, from conception to archive. Investing in a ClM system means you don’t have to worry that part of the contract process will fall through the cracks if you’re in the bidding phase, inactive during negotiations, ready to sign, or need to review data from existing contracts. Sources: 11

Cited Sources